Managing

technical uncertainties

Statistics,

RAMS

& Quality Management

Search

this site  Search

this site Search

this site

|

|

|

Reliability

Block Diagrams

Reliability

Block Diagrams are useful

for visualizing and analyzing complex systems. The system is broken

down into functional blocks. Functional

blocks then are connected with arrows in order to depict a kind of

"functional flow".

Complex systems have at least one of the following

characteristics:

- Parallel branches (redundancy)

- Fault tolerance

- Network structure (e.g. production line)

- Dedicated maintenance philosophy (e.g. repair of block A affects

block B)

The functional blocks, start and end point are connected with

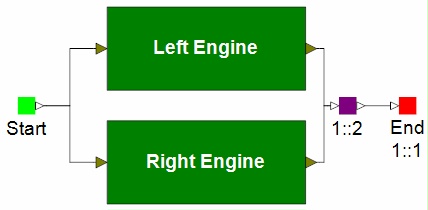

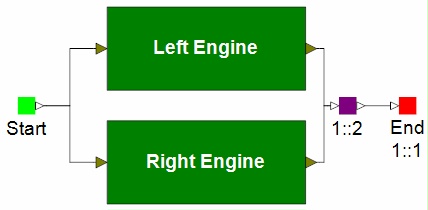

"functional flow" arrows according to the system architecture. Reliability Block Diagram

As long as there is at least one

uninterrupted connection between start

and end (a so called path set, or success path), the system is

considered functional.

A good example may be a twin engine aircraft, which will be also used

in the Markov paragraph in order to demonstrate the differences between

Reliability Block Diagram and Markov.

Twin engine aircraft can safely fly with only one engine. However,

if one engine fails, the aircraft must fly directly to the nearest

eligible alternate airport.

The "1::2" below the node means that at

least one out of two incoming paths must be functional in order

to keep the system functional. In this example, each of the two paths

consists of one engine.

Depending on the capability of the Reliability Block Diagram software,

many system parameters can be calculated, for example:

- Failure rate, MTBF

- Reliability R

- Availability A

- Repair cost, repair time

- Optimal maintenance interval (depending on criteria)

- Optimal number of spares (depending on criteria)

The reason why we use the twin engine

example is to show the limitations of Reliability Block Diagrams in

comparison to Markov analysis.

In RBD, the aircraft is considered to have failed as soon as both

engines fail. In practice however this is not necessarily the case,

because the aircraft can fly safely even with both engines failed ...

at least for 10 minutes. This would probably be enough time for the

crew to restart one of the engines in order to make it to the nearest

alternate airport.

There is a further limitation: With one engine failed, the remaining

engine must work harder in order to keep the aircraft airborne. This in

turn would cause a higher failure rate for the remaining engine.

Reliability Block Diagram cannot handle this, but Markov analysis can.

Previous

Topic

Next Topic

Privacy Policy